Anemoi installs 35-meter-tall composite rotor sails on Sohar Max maritime vessel

Carbon fiber-reinforced epoxy composites are key to building these long-lasting wind propulsion technologies for energy-efficient watercraft.

Source | Anemoi Rotor Technologies

Anemoi Marine Technologies (London, U.K.) has announced the completed installation of five composite rotor sails onboard the 400,000 dwt very large ore carrier (VLOC), Sohar Max, reportedly making it the largest maritime vessel to receive wind propulsion technology to date. Sohar Max, a first-generation Valemax, was built in 2012 in China’s Rongsheng shipyard and unveiled in November 2023.

As part of the collaboration between Brazilian mining giant Vale (Rio de Janeiro), Omani shipowner Asyad and Anemoi, the 35-meter-tall, 5-meter-diameter rotor sails were retrofitted onboard Sohar Max in October 2024. In addition, Anemoi has installed its bespoke folding deployment system, which will enable the sails to be folded from vertical to mitigate any impacts on the vessel’s cargo handling operations.

Installation of the rotor sails on the Sohar Max are expected to reduce the vessel’s fuel consumption by up to 6% and cut carbon emissions by up to 3,000 tonnes annually. Sohar Max has just completed a voyage to Tubarao, during which the rotor sail test period began and testing will continue on future voyages.

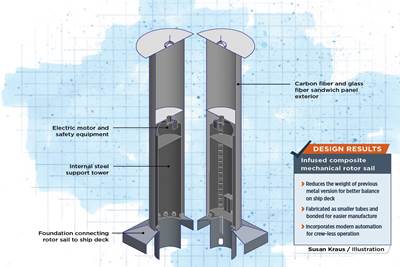

The largest rotor sail in Anemoi’s product range is 5 meters in diameter and 35 meters high, with a 9-meter-diameter top disc. Its sails use a host of composite components, including:

- The rotor skin – the cylindrical, spinning part of the rotor which has internal composite and steel structures to support it.

- Top disc – an aerodynamic “end plate” that stops high-pressure air from the aft side of the rotor spilling over to its low-pressure forward side.

- Rotor sail – a static cylindrical part below the rotor that prevents air flow from leaking in and out.

Anemoi’s rotor skin comprises glass fiber-reinforced epoxy polymer, developed via a manufacturing method that uses a combination of pultrusions wrapped in a filament winding process. The top disk is vacuum infused with the addition of recycled PET foam core for stiffness and strength.

What is the reason behind the use of these specific materials? “Rotor sails operate at hundreds of revolutions per minute, experiencing billions of fatigue cycles over its lifetime,” explains Luke McEwen, Anemoi technical director. “Structurally, it acts as a large beam to withstand pressure coefficients of 10 or more, and as it rotates, each part of the rotor sail sees fully reversing stresses. This results in fatigue loading even more severe even than on a wind turbine blade. Epoxy composites are ideally suited to withstanding such high fatigue loads and their fatigue performance is well understood and proven in wind turbine blade applications. Anemoi has also conducted fatigue testing of specific composite design details to confirm the strength of the rotor skin through its full 25-year design life.”

As standard, Anemoi rotor sails are permanently fixed to the deck. However, the company also offers various deployment systems, including folding deployment (left), transverse rail deployment (center) or longitudinal rail deployment (right). Source | Anemoi brochure

In addition to good fatigue performance, corrosion resistance is a key advantage of composites and essential for withstanding marine environments. Composites are also lightweight, which is important in ensuring the overall weight of the rotor sail is as low as possible. “The rotor skin weight has a knock-on effect on the loads on the supporting steel tower inside the rotor sail, the strength of the foundation and the amount of cargo the ship can carry,” adds McEwen, “therefore it’s vital to use materials that are durable but lightweight.”

Anemoi’s supply partners in China build its rotor sails to the company’s design and specifications. For the composite components, Anemoi has been partnering with Zhongfu Lianyungang Composites (Jiangsu) since 2020. Zhongfu is considered to be one of the top three independent wind turbine blade manufacturers in the world, specializing in blade research, design and manufacturing, boasting a capacity of more than 4,000 wind turbine blades per year.

According to Anemoi, composite materials are essential for building robust, long-lasting rotor sails that are able to withstand the harsh marine environment with minimal maintenance. “There is a huge and increasing appetite for wind propulsion systems like rotor sails, which is reflected in various market research reports,” McEwen notes. Its focus, heading into the future, is on developing a manufacturing method that can be automated to the maximum extent possible, using lowest cost but high-performance composite materials, in order to scale up production to hundreds of units per year as the market grows.

Related Content

Sulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MorePlant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreRead Next

Norsepower installs tiltable composite rotor sails on Sea-Cargo RoRo

Installation of two 35-meter-tall rotor sails are estimated to reduce fuel consumption, fuel costs and emissions by as much as 25%.

Read MoreModernizing the mechanical rotor sail

Composites are key for Norsepower’s award-winning redesign of a century-old rotor sail for reducing carbon emissions on passenger and cargo ships.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More