Cevotec’s fiber patch placement is part of digital process chain for automated composite prosthetics

Multiple partners work to develop automated data collection, composite laminate generation for customized medical applications using FPP technology in German-funded Patch2Patient project.

Launched in 2019, the German Federal Ministry of Education and Research co-funded the research project “Patch2Patient,” (ID 02P18C090 to 02P18C096) to provide digital process chain technology for manufacturing medical products using lightweight composites. As project coordinator, Cevotec (Munich, Germany) is working with partners Carbovation (Friedrichschafen), Mecuris (Munich), Guenther Bionics (Magdeburg), Ottobock (Duderstadt) and Fraunhofer IPA (Stuttgart). Cevotec’s fiber patch placement (FPP) technology provides the project’s baseline for automating carbon fiber-reinforced composites due to its ability to produce highly complex shaped and customized composite parts.

Fiber-reinforced polymer (FRP) composites play a major role in the production of customized medical devices. They are the material of choice especially for heavily loaded extracorporeal parts like prosthetics and orthotics. However, the majority of such products are still produced by hand, increasing cost, which reduces availability for many patients. Manual manufacturing also makes it difficult to track and improve quality parameters, while the required customization to each patient has made automation a challenge using current composites manufacturing technologies.

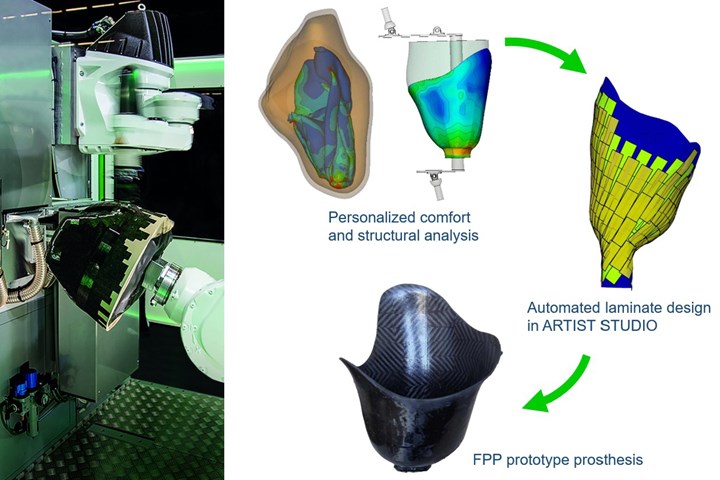

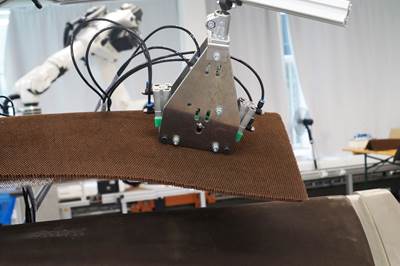

Patch2Patient has involved a fundamental investigation and enhancement of the FPP production process in order to meet the demands for manufacturing customized composite prosthetics and orthotics. Project partners are analyzing different methods and developing a prototype digital workflow to process specific patient data for the subsequent customized design of the required part. The overall goal of the Patch2Patient project is to create a solid baseline for an automated digital process chain from the collection of the patient data to the optimized design of the composite part.

“We are analyzing possible approaches to incorporate patient data into our Artist Studio laminate design software,” explains Thorsten Groene, CEO and cofounder of Cevotec. “In addition, we are currently developing a dedicated feeding and cutting unit [FCU] as a key enabler for an FPP process suitable for the efficient and economical production of medical composite products. We aim to make this FCU capable of handling different fiber materials, such as carbon and glass fiber, and for processing patches of variable lengths.” He notes the FCU will also be able to handle cost-efficient towpreg materials as well as specialized fiber materials with improved fatigue and impact resistance.

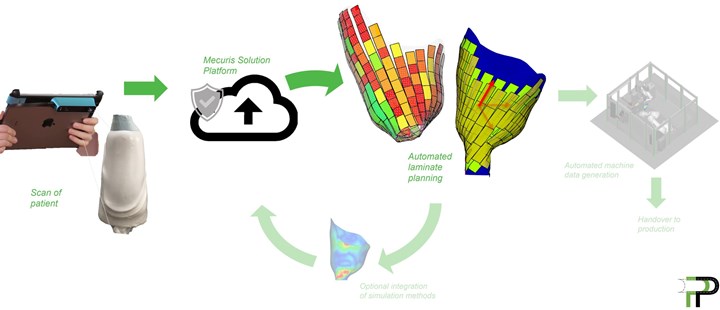

Digital chain from 3D scan to FPP laminate design generated by Artist Studio. Photo Credit: Patch2Patient project, Cevotec

Cevotec reports recent results from work project partner and medical software expert Mecuris. The goal was to set up an automated process to design and create composite laminates for patient-individual prosthetic legs. Mecuris extended its existing Solution Platform for editing 3D scans to also support the definition of fiber orientations, reinforcement zones and other properties specific to FPP. This adaptation enabled options for special adjustments, if required.

After the necessary information was provided by the orthopedic technician, the 3D scan data from Mercuris was then sent to a Cevotec server where the layup planning was automatically performed. To achieve this, Cevotec developed a new cloud-hosted application programming interface (API) with the Mercuris adapted software solution. A download link for the 3D scan in the common STL format, as well as the laminate metadata and the credentials for the upload of the results were then submitted to Cevotec’s Artist Studio software. The elaborate scripting features of this software were then used to create and optimize a suitable FPP laminate.

Based on the simulation work conducted by project partner Fraunhofer IPA, an optimal design was previously identified for a generic prosthetic. This abstract laminate definition was consequently applied to the actual geometry of the desired prototype by first defining an intersection of the part with a user-defined reference plane. The resulting contour was used as a reference for the fiber orientation. Additional curves — parallel or oriented at an angle relative to the contour — were then derived from it. These curves described the local orientation of the patches that were generated in the subsequent step. The manufacturing of the resulting patch-based laminate was then also automatically simulated, and the patch lay-up was finally uploaded to the Mecuris Solution Platform where it could be reviewed by the user.

This application shows the flexibility of the Artist Studio software’s automation functionalities, especially when integrating the creation of an FPP laminate into a more complex software toolchain. The Patch2Patient project is scheduled to be completed in 2023.

Related Content

Automated robotic NDT enhances capabilities for composites

Kineco Kaman Composites India uses a bespoke Fill Accubot ultrasonic testing system to boost inspection efficiency and productivity.

Read MoreCorebon induction heating

This sidebar to CW’s August 2024 feature article reviews this technology for more efficient composites manufacturing and why it aligns with Koridion active core molding.

Read MoreASCEND program completion: Transforming the U.K.'s high-rate composites manufacturing capability

GKN Aerospace, McLaren Automotive and U.K. partners chart the final chapter of the 4-year, £39.6 million ASCEND program, which accomplished significant progress in high-rate production, Industry 4.0 and sustainable composites manufacturing.

Read MoreAurora reveals latest SPRINT X-Plane design concept

An Aurora and Boeing team advances its high-speed, vertical lift concept to the preliminary design phase, which features three lift fans, a more refined composite exterior and an uncrewed cockpit.

Read MoreRead Next

ACoSaLUS project updates for automated sandwich panel layup

Cevotec and project partners have made significant progress in line with 2023 completion, including improvement of automated handling, patch vision inspection, and the laminate design and patch placement process.

Read MoreSolico composite engineers bring comfort, flexibility to new Axile Bionics ankle prosthetic

Lunaris is Solico’s first medical prosthesis design, using advanced composite components to reduce weight and outer dimensions, and enhance wearability.

Read MoreLighter, stronger, faster bionic hand aided by composites design

Psyonic’s touch-sensing prosthetic hand leverages bionic technology, 3D printing and a carbon fiber composite exterior for light weight, high strength and high-tech functionality.

Read More