Composites end markets: Energy (2025)

Despite political and supply chain challenges, renewable and nuclear energy continue to grow in use. Composite materials enable current and future energy technologies across sectors.

Composites have long been used in energy-related structural applications like wind turbine blades and various components in oil and gas extraction. New materials and innovations in composites are also helping to power next-generation energy, including offshore wind, industrial solar farms and satellite-based solar arrays, river and marine energy systems, and pipelines for green hydrogen transport. Sources (clockwise from top left) | Getty Images, Kerberos Engineering, ORPC, Hive Composites

Global energy demand grew by 2.2% in 2024 (almost twice the average rate over the past decade), led by higher electricity demands for cooling, industry, electrification of transport and the growth of AI data centers, reports the International Energy Agency (IEA, Paris, France) in its latest “Global Energy Review” released in March 2025.

While the IEA reports that demand has risen for all fuels and technologies (renewables, oil, natural gas, coal, nuclear), 80% of the growth in global electricity generation in 2024 was provided by renewable sources and nuclear power, making up 40% of total generation for the first time.

Many of these energy and electricity generation technologies are enabled by composite materials in various ways, and this report, while not comprehensive, summarizes the landscape and recent technologies for composites in these industries.

Wind energy market and composites innovations

Wind turbines are the largest application for composite materials, incorporating significant amounts of glass fiber per blade as well as, increasingly, carbon fiber for reinforcing spar caps. Many wind turbine nacelles are also manufactured from composites.

According to the Global Wind Energy Council’s (GWEC, Brussels, Belgium) “Global Wind Report 2025” released in April, 117 gigawatts (GW) of new wind energy was installed globally in 2024, about the same as global installations in 2023, which was the best year for wind yet recorded. This is all despite significant challenges to the industry, including interest rate increases, inflation, supply chain pressures, trade barriers and tariffs, and political uncertainty.

In 2024, China led global installations, followed by the U.S., Germany, India and Brazil. Though GWEC reports a decline in new installations in North America, Latin America and Europe compared to 2023, there was also “record growth” in several regions, including 7% year-on-year growth in the Asia-Pacific region, and 107% year-on-year growth in the Africa and Middle East region led by Egypt and Saudi Arabia.

It is worth noting that Reuters reported in July 2024 that six of the top 10 global wind turbine manufacturers (Goldwind, Envision, Windley, Mingyang, Sany and DEC) are Chinese and provide turbines mostly for installation in China, though these companies are also starting to move into other regions such as Europe. The other listed top turbine manufacturers are Vestas, Siemens Gamesa, and Nordex, all headquartered in Europe, and GE Vernova, based in the U.S.

In addition, Stratview Research (Raipur, India) explained in a November 2024 webinar on the Indian composites landscape that wind blade spar caps are currently the largest application of carbon fiber composites in India and growing, with demand expected to more than double by 2030.

Currently, GWEC forecasts a compound average growth rate of 8.8% for the wind industry, meaning another 981 GW of capacity globally by 2030. However, Jonathan Cole, chair of GWEC, writes, “We are not going fast enough — the rate of installation of wind energy needs to continuously increase, not hold steady or decrease, if we are to hit the important 2030 tripling up target [to meet global decarbonization goals] … We need to keep pushing to go faster.”

Research and innovation in wind turbine technology

To support this growth, there are many innovations in development in the field of wind blade technology, from optimizing manufacturing methods and materials to more efficient or higher-capacity designs.

A few examples reported in the past year include:

Larger turbines and longer wind blades. The longer the blade, the more wind energy can be captured. Wind OEMs globally have been introducing larger-capacity wind turbines featuring increasingly long blades for both onshore and offshore turbines, despite reported “stalling” in recent years due to supply chain and financial issues.

The pace of scale-up has been particularly fast in the Chinese market, GWEC reports, with six Chinese OEMs having launched 20+ megawatt (MW) offshore models as of the end of 2024. This includes DongFang Electric (Guangdong), which announced in November 2024 that it had produced its first 26-MW offshore wind turbine, reported to be the largest yet built. The company says that a single turbine can produce 100 million kilowatt-hours (kWh) of clean electricity annually at a wind speed of 10 meters/second, meeting the annual electricity needs of 55,000 households.

Global OEMs continue to launch larger, higher-capacity turbines for onshore and offshore use, like MingYang’s latest 18-20 MW and future planned 22-MW turbine. Source | MingYang Smart Energy

In August 2024, MingYang Smart Energy (Guangdong) is reported to have installed the first of its 18- to 20-MW offshore wind turbines, called the MySE18.X-20MW, in Hainan, China. The platform is expected to be able to generate 80 million kWh annually. The company has said it is also working on a larger 22-MW turbine. Hengshen Co. Ltd. (Danyang City) has announced that it is the exclusive carbon fiber fabric supplier for one of MingYang’s ultra-large offshore wind turbine platforms, the 143-meter-long blades for the MySE292.

Aiming to compete with China, Siemens Gamesa (Zamudio, Spain) is reported by multiple sources to have installed a prototype 21-MW offshore turbine in Denmark. Meanwhile, Vestas’ (Aarhus, Denmark) V236-15.0MW model has secured more than 6 GW in confirmed orders globally so far, GWEC reports.

Onshore turbines are also getting larger, and their blades longer. For example, Chinese wind blade manufacturer Sany Renewable Energy (Beijing) announced the 2024 rollout of a 131-meter wind blade for its SY1310A. Sources have reported that the blades will be used for the company’s 10-MW onshore turbines, and later potentially for its announced 15-MW turbines, said to be the largest onshore turbine yet developed.

The blades are said to be manufactured from fiberglass pre-quilting technology, carbon fiber composite spar caps, long-distance automatic infusion technology for large composite blades and 3D design for blind bonding inserts used in the blade’s trailing edge. Polyurethane structural parts have also been incorporated to enhance the recyclability of the blades.

GWEC also reports new onshore upgrades over the past few years by Nordex (Hamburg, Germany), Vestas and Enercon (Aurich, Germany).

Innovations in spar cap materials. One enabling technology for longer, more efficient blades is carbon fiber-reinforced polymer (CFRP) composite spar caps, offering lighter weight and higher stiffness and strength compared to glass fiber composites.

We4Ce's blade prototype, shown here in a test rig, features an infused carbon fiber/epoxy spar cap as a lower-cost alternative to pultruded profiles. Source | We4Ce

Typically, these CFRP spar caps are made via pultrusion, but other material options are also being developed. For example, rotor blade design and technology supplier We4Ce (Almelo, Netherlands) has developed a 2.5- to 3-MW rotor blade prototype for wind turbine manufacturer Suzlon Group (Pune, India) that includes a spar cap made from dry carbon fiber infused with epoxy as an alternative to a more common pultruded profile. According to We4Ce, the use of infusion offers uniform material distribution that reduces risks of cracks and delamination, and also enables use of more cost-effective dry fabrics.

As of January 2025, We4Ce reported that a prototype blade had passed final validation testing for IEC61400-5:2020 certification, the production standard for engineering integrity of wind turbine blades.

Optimizing wind blade manufacture. To increase wind turbine production and installation, many companies are working on more efficient manufacturing processes for wind blades, including application of machine learning or automation.

Researchers used RFID-based temperature and curing sensors in a process guided by machine learning algorithms. Source | TPI Composites, University of Texas

For example, wind blade manufacturer TPI Composites Inc. (Scottsdale, Ariz., U.S.) announced in 2024 that it is working with the University of Texas Dallas on research aimed at optimizing the wind blade curing process. The research involves applying physics-informed machine learning algorithms that simulate and optimize the process through multi-zone temperature control.

Use of these models “bridges the gap between deterministic multiphysics simulations and kinetics of cure as happening on the shop floor,” says Dr. Shaghayegh Rezazadeh, TPI lead engineer. “This process leverages different heating zones integrated in TPI molds to achieve the desired mechanical properties while optimizing the cure cycle time to ensure consistent quality and enhanced productivity for the blades manufactured by TPI.”

The project, funded by the Office of Energy Efficiency & Renewable Energy, is expected to lay a foundation for smart composites manufacturing and provide a competitive performance and cost advantage for industries adopting these technologies, in terms of cost savings and performance improvement.

A robotic arm at NREL’s Colorado facility automates trimming, grinding and sanding of blades. Source | Werner Slocum, NREL

In addition, researchers at the U.S. Department of Energy’s (DOE) National Renewable Energy Laboratory (NREL, Golden, Colo., U.S.) are working on developing robotic arm-based systems for automating more parts of the blade manufacturing process. Although robots have been used by the wind energy industry to paint and polish blades, NREL is demonstrating the ability of a robot supplied by Orbital Composites (San Jose, Calif., U.S.) to trim, grind and sand blades.

Lightning strike protection (LSP). To increase durability and decrease repair costs and maintenance downtime, developments in more effective LSP are in progress. For example, researchers at the DOE’s Oak Ridge National Laboratory (ORNL, Tenn., U.S.) have demonstrated effectiveness of a 6.5-foot turbine blade tip manufactured from a combination of glass fiber and a customized conductive carbon fiber developed by ORNL. This carbon fiber is said to be key to dispersing electrical energy across the blade surface.

This fiber was also designed to be low cost — to replace typical glass fiber in a blade tip — able to be integrated into the blade using common manufacturing methods, and fully recyclable. The lab is continuing to advance this technology toward commercial adoption.

TouchWind’s floating turbines are said to be able to withstand storm-force winds. Source | TouchWind

Novel floating offshore wind turbine designs. There are a variety of floating offshore wind platforms in development, and composite materials can be used in both the platform designs as well as the turbine blades where light weight or other properties are needed. For example, We4Ce has announced its tiltable, self-lifting, one-blade glass fiber/epoxy rotor design delivered for testing on startup TouchWind B.V.’s (Eindhoven, Netherlands) floating TW6 turbine. Engineered to withstand wind speeds of up to 250 kilometers/hour — the highest wind class in wind industry standards — the future commercial version is expected to cost significantly less than traditional turbines while delivering higher energy yields.

Demonstration of bio-based materials for wind technology. A variety of polymers and fibers derived from plants or other natural sources have been developed in an effort to replace traditional fossil fuel-based materials in numerous applications, including wind energy technology.

NREL’s PECAN resin is derived from sugars and said to perform on par with standard resins and increase recyclability. Source | Werner Slocum, NREL

For example, NREL has published research on the development of what it calls a “biomass-derivable” resin nicknamed “PolyEster Covalently Adaptable Network” (PECAN) specifically for use in the manufacture of wind blades. PECAN is said to be sourced from sugars, able to be recycled using a chemical process and has been demonstrated to perform on par with industry standard resins. The researchers tested the resin’s manufacturability through the fabrication of a 9-meter prototype blade.

In the EU, EOLIAN is a 3.5-year, multi-partner project kicked off in June 2024 with the goal of developing a new generation of smart, sustainable wind turbine blades with longer lifetime, improved reliability and higher sustainability.

EOLIAN blades are expected to be repairable and recyclable with integrated sensors to enable structural health monitoring (SHM), including combination of recyclable vitrimer resins with natural basalt fibers as a replacement for glass fiber.

Alternative wind energy systems. It’s worth mentioning that there are other wind-based energy systems in development besides traditonal turbines, including those called airborne wind energy (AWE) systems. These use kites or drones tethered to a ground-based station and move in helical or figure-eight patterns to capture energy from high-altitude winds.

CTL’s airborne wind energy system features a composites-intensive kite that is designed to capture high-altitude winds. Source | CTL

Composites Technology Laboratory (CTL, Galway, Ireland) is one company working in this area through the project “Hibernian Airborne Wind energy Kites” (HAWK) funded by the Sustainable Energy Authority of Ireland (SEAI). In the HAWK project, CTL and its partners are working on challenges to AWE development and certification including materials, product safety/regulation, technology feasibility and developing effective supply chains.

Wind blade recycling

Wind blades aren’t only a top application for composites manufacturers — they’re also a key topic within the recycling conversation. In recent years, numerous startups and technologies have arisen to tackle the problem of what to do with the composite components of wind blades when they are decommissioned.

There are several types of recycling processes developed for recycling wind blades, including mechanical processes that involve shredding blades down into smaller pieces for reuse in new applications, incineration and energy capture, or various methods of separating out and reclaiming the fiber (and sometimes also the resin) from the parts through chemical (solvolysis) or heat-based (pyrolysis or thermolysis) methods.

As an example of mechanical recycling, in 2024, Regen Fiber (Fairfax, Iowa, U.S.) opened a facility expected to process up to 30,000 tons of blades per year through the company’s recycling process, which shreds the blades, extracts usable components and transforms them into premium products that are used in construction materials such as concrete.

Isodan Engineering ApS (Holeby, Denmark) has translated its paper shredding technology into a solution for shredding and grinding wind turbine blades housed in mobile shipping containers.

Acciona’s WALUE process treats waste using a low-temperature thermal process (left) that outputs clean fibers for reuse in applications like automotive trunks. Source | Acciona

Acciona Energía, an energy-focused subsidiary of infrastructure solutions company Acciona (Madrid, Spain), has received awards for its composite recycling technology including its industrial-scale wind blade recycling plant in Lumbier, Spain and the use of its output in the El Ganso x Acciona sneaker and surfboards by Draft Surf. The company’s patented WALUE process involves first shredding and then heat treatment, resulting in fibers as well as oils that can be used to manufacture new resins. Read more in CW senior technical editor Ginger Gardiner’s JEC World 2025 highlights.

WindLoop, a startup comprising students at Yale University (New Haven, Conn., U.S.), has developed a process using what it calls “green chemistry principles,” to effectively separate the fibers and resin in blades. WindLoop’s solution is said to recover more than 90% of turbine blade material and 97% of the overall value of the turbine blades.

In addition, there are many ongoing and completed collaborative research efforts with the goal of tackling wind blade recycling using a variety of approaches. A few of these include:

- The Horizon Europe REFRESH (Smart dismantling, sorting and REcycling of glass Fibre REinforced composite from wind power Sector through Holistic approach) project, led by an 11-member European consortium, is using a novel blockchain traceability platform to cover the entire value chain from sorting to recycling to new end products.

- DecomBlades, a 2021-2023 project led by composites industry partners and research institutes, resulted in pilot-scale pyrolysis and shredder facilities with plans to continue scale-up.

- The ZEBRA (Zero wastE Blade ReseArch) project, led by the French Institute for Technological Research (IRT Jules Verne, Bouguenais), has demonstrated recycling of thermoplastic composite wind blades made from Arkema’s (Cologne, Germany) recyclable Elium resin.

- SusWIND, a collaborative program started in 2021 by the National Composites Centre (Bristol, U.K.), is focused on advancing wind blade recyclability in the U.K.

- A team of University of Maine (UMaine, Orono, U.S.) researchers began a project in 2024 to explore recycling wind blades as feedstock for 3D printing.

- The Horizon Europe-funded initiative ECORES WIND kicked off in September 2024 to develop resin system alternatives that promote recyclability, extended lifespan and enable efficient decommissioning processes.

- The 14-partner, 4-year REWIND (Efficient Decommissioning, Repurposing and Recycling to increase the Circularity of end-of-life Wind Energy Systems) project, kicked off in May 2024, is developing technologies for dismantling, inspection, recycling and reuse.

There are also a growing number of companies and initiatives working on ways to reuse entire wind blade structures, or pieces of them, as-is. They are aiming to provide fast, low-energy-intensive solutions for decommissioned blades while other recycling methods are maturing. Wind blades have so far been used to construct a variety of creative applications, such as bridges, outdoor furniture pieces and parking garage facades.

For example, the Re-Wind Network is a multi-university collaborative organization formed in 2017 dedicated to finding uses for decommissioned wind blades, such as a 5-meter-long wind blade-based pedestrian bridge installed in Ireland in 2022.

Canvus Inc. repurposes decommissioned, fiberglass composite wind blades and other materials into functional, creative outdoor furniture that can be donated to communities. Source | Canvus Inc.

Canvus Inc. (Rocky River, Ohio, U.S.) combines pieces of repurposed wind blades with other upcycled materials to form outdoor furniture that can be purchased or donated to a community. The company’s community focus has also led to partnerships with local artists to paint custom designs on certain furniture pieces, turning them into functional art.

The GP Renewables Group (Hamburg, Germany) manufactures both bridges and outdoor furniture, as well as other products like geotechnical blocks for use in construction.

Future use cases are also in development, such as a planned parking garage façade in Lund, Sweden, that will feature decommissioned wind blades for nonstructural elements.

Alongside development and scale-up of recycling technologies, wind blade manufacturers and OEMs are also working at the same time to make new wind blades more recyclable.

Siemens Gamesa (Zamudio, Spain) has announced a goal to produce 100% recyclable wind blades by 2040. In 2021, the company launched its first RecyclableBlade, debuting a resin reported to enable recovery of both resin and fiber at the blade’s end of life (EOL) through a solvolysis process. In 2022, Siemens Gamesa announced a partnership with resin supplier Swancor (Nantou, Taiwan) for the supply of Swancor’s EzCiclo epoxy resin that is said to enable fiber and resin reclamation, also through a specialized solvolysis process. The partners newly solidified their collaboration in 2024, announcing that by 2026 all resin supplied to Siemens Gamesa by Swancor would be recyclable.

In January 2025, Swancor announced a memorandum of understanding (MOU) with Adani New Industries Ltd. (Gujarat, India), with the goal supplying EzCiclo for building India’s first “fully recyclable” wind farm.

The VX175 turbine, announced in early 2025 and expected to launch commercially this year, is also said to be fully recyclable. Purpose-built for commercial and industrial rooftops, the VX175 is a product of renewable energy company Ventum Dynamics (Stavanger, Norway) and ExoTechnologies (Douglas, Isle of Man, U.K.), which developed the turbine’s reportedly recyclable, natural fiber-reinforced thermoplastic “Danu” composite material.

Ventum Dynamis’ rooftop turbine is said to be able to capture wind from all directions, and is manufactured from a natural fiber-reinforced thermoplastic composite. Source | ExoTechnologies, Venture Dynamics

According to Venture Dynamics’ website, “the vane shroud design accelerates wind capture, enabling a greater volume of air to pass through the turbine. This focused wind is directed straight toward and across the entire rotor disc with minimal energy losses, optimizing power capture at the rotor.” Its omnidirectional design also makes it capable of capturing wind from all directions, delivering up to 3,000-5,000 kWh annually.

There is also ongoing research in this area. For example, in 2024 the EU-funded Blade2Circ project was announced by the Aitiip Technology Center (Zaragoza, Spain), with the goal of developing a new generation of wind turbine blades using high-performance bio-based composite materials.

Other renewable energy applications

Wind turbine blades may be the largest users of composite materials in the renewable energy space, but other renewable energy applications also use composites , such as hydroelectric and tidal turbine blades and wave energy systems, as well as solar panel and plant components.

Solar applications

One challenge to the development of concentrated solar plants (CSP) is the high heat involved. CSP work by using mirror-like heliostats to concentrate sunlight to heat molten salt, which in turn stores energy. Temperatures can exceed 700°C and degrade traditional materials like metals.

Composites — specifically, ceramic matrix composites (CMC) — offer one solution. Nonprofit scientific and R&D organization SRI (Menlo Park, Calif., U.S.) has pursued research in CMC for decades and is currently part of a U.S. DOE project to improve CMC for solar energy and energy storage applications.

SRI has developed novel ceramic matrix composites (CMC) aimed to enable high-concentration solar plants and other renewable energy systems. Source | SRI

As reported by CW’s Ginger Gardiner, SRI has developed a process that is said to produce CMC with increased durability and resistance to corrosion from both high temperatures and molten salt compared to metals, while reducing manufacturing costs by 50% versus traditional CMC. Instead of typical polymer infiltration and pyrolization (PIP) — which requires up to 10 repeated cycles to achieve a sufficiently dense carbon fiber-reinforced carbon and silicon carbide (C/C-SiC) matrix CMC — SRI uses a functionalized benzoxazine precursor resin loaded with ceramic particles. When combined with continuous or chopped carbon fibers, the resulting preceramic green body can be pyrolized without repeated and time-consuming infiltration cycles to produce a sufficiently dense CMC — reducing what has historically required weeks to months down to 3-5 days.

For more portable solar panels — those mounted on rooftops or marine vessels, for example, or those launched into space on satellites — making sure the panel itself is as light as possible can be a vital consideration.

There are a variety of examples of composites used to lightweight solar panels today, some of which also incorporate recycled materials. For example, solar panel producer Solarge (Weert, Netherlands) and honeycomb sandwich material manufacturer EconCore (Leuven, Netherlands) launched a lightweight, fully circular composite and honeycomb solar panel in 2023 that is said to reduce the weight of solar installations by up to 65% for rooftops.

Levante’s custom and standardized solar panels integrating recycled carbon fiber (rCF), thermoplastics and silicon solar cells to maximize both light weight for portability and rigidity for durability and protection while in use on boats, recreational vehicles or other applications. Source | Levante

Targeting consumer and marine applications, startup Levante (Bari, Italy) has developed a series of standardized, portable solar panels integrating recycled carbon fiber (rCF), thermoplastics and silicon solar cells to maximize both light weight for portability and rigidity for durability and protection while in use on boats or recreational vehicles. The company launched its first line of standardized panels in late 2024 and also offers customized designs.

Levante is also working on an EU-funded project with ACS Composites Solutions Srl (Tortoreto, Italy) to expand its solar panel technology including the incorporation of bio-based resins and curved geometry suitable for applications like car roofs or other vehicle exteriors.

A constellation of satellites is prepped for deployment, housed within a rocket's payload bay. These satellites are equipped with rapidly manufactured composite deployable solar arrays. Source | Kerberos Engineering

Composites are also used to lightweight and increase performance of solar arrays for satellites. For example, CW contributing writer Stewart Mitchell writes about the use of TeXtreme (Borås, Sweden) 0/90 woven carbon fiber spread tow fabrics in the manufacture of deployable satellite solar array structures by Kerberos Engineering (Murcia, Spain). The use of these materials is reported to reduce the resources required for manufacturing these arrays by 90% compared to conventional techniques, while also improving precision during layup and overall robustness of the product.

Announced in December 2024, Airborne Aerospace B.V. (The Hague, Netherlands) will supply high-precision panel and yoke substrates for Airbus Netherlands B.V.’s (Leiden) Sparkwing solar arrays, a critical component of MDA Space’s Aurora satellite product line that aims to expand communication networks globally.

Under the contract, Airbus will deliver Sparkwing solar arrays featuring two wings with five panels each, providing a photovoltaic area exceeding 30 square meters. Airborne will manufacture more than 200 high-precision and ultra-stiff composite substrate panels for the project.

Beyond satellites, carbon fiber and a flexible polymer were reportedly used in the development of the booms used to launch NASA’s (Washington, D.C., U.S.) ACS3 solar sail system in summer 2024. According to Aviation Week, the “solar sail uses a novel expanding tubal boom system made of flexible polymer and carbon fiber materials that can be rolled up inside a CubeSat for launch and then unrolled when deployed.” The four fully deployed sails, made of reflective polymer sheets, harness the energy of photons emitted from the sun to propel the spacecraft.

River, tidal and wave energy technologies

There are a variety of river or tidal turbine technologies either commercialized or in development today, many of which include composite struts, foils or other composites for maximum efficiency and durability. One is the AR1100 tidal turbine by Proteus Marine Renewables (Bristol, U.K.), which the company announced in March 2025 was successfully developed in Japan’s Naru Strait to generate 1.1 MW of clean energy. The AR1100 tidal turbine generator is said to feature a horizontal-axis rotor with three composite blades, designed for optimal efficiency in tidal currents.

ORPC’s RivGen hydrokinetic river turbines are designed to provide clean power to remote communities. In the pictured design, the yellow struts and black foils are made from carbon- and glass fiber-reinforced polymer dry braid and resin transfer molding. Source | ORPC, via Hawthorn Composites

Another example is the company Ocean Renewable Power Co. (ORPC, Portland, Maine, U.S.), which builds hydrokinetic power generators for use in rivers, called RivGen Systems, enabled by fiberglass composite struts and carbon fiber composite foils manufactured by partner Hawthorn Composites (Miamisburg, Ohio, U.S.). The company has installed several commercial systems to provide clean power to remote areas, and continues to scale up its production.

ORPC is simultaneously working on development and testing of next-generation systems, including a marine version of its technology, first through the EU-funded CRIMSON project, in which a system with 5-meter foils was built and tested, and continuing with a project called X-Flow led by Queen’s University Belfast. In November 2024, ORPC announced that its Dublin, Ireland-based site had successfully deployed a marine hydrokinetic turbine to the Strangford Lough Tidal Test Site in Northern Ireland. The next phase of the X-Flow project will include the testing and monitoring of the turbine through a range of operating conditions.

In April 2025, ORPC Ireland partner ÉireComposites (Galway, Ireland) announced that it, along with ORPC and the University of Galway’s Advanced and Sustainable Manufacturing and Materials Engineering (ASMME) group, is leading a new TidalHealth project aimed at integrating CFRP tidal turbine foils with 3D-printed optical fiber sensors to enable continuous SHM of these systems.

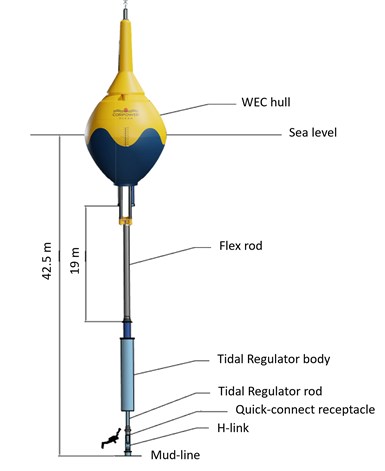

Another promising ocean energy technology is wave energy converters (WEC), devices that use the motion of ocean waves to generate electricity. Various types of WECs have been developed, and many of these concepts work in a similar way to hydroelectric turbines: A column-, blade- or buoy-shaped device sits on top of or under the water, where they capture the energy generated by ocean waves acting on the device. That energy is then transferred to a generator that converts it to electricity.

CorPower Ocean’s first full-scale prototype, manufactured from filament-wound glass fiber composites, was deployed in 2021 and has since provided data on efficiency and storm survivability. Source | CorPower Ocean

One WEC developer making extensive use of composites technology is CorPower Ocean (Stockholm, Sweden), which reports that it has secured €95 million in funding from public and private investors since its founding 2012 and opened operations in Sweden, Norway, Portugal and Scotland, with plans to expand into the U.S. It has successfully demonstrated four generations of its buoy-shaped WECs with goals of commercialization. The company is currently operating several projects proving out the storm survivability and efficient power generation of its WECs, including its first full-scale WEC prototype, C4, which was deployed for ocean trials in 2021 and features a 9-meter-diameter, spherical hull manufactured from filament-wound GFRP.

Composites in oil and gas applications

Composites’ inherent corrosion resistance and light weight have led to adoption of composites over metals for a variety of wellhead protection components, frac plugs for hydraulic fracturing (fracking), offshore oil and gas pipes and more. Composites can also serve as efficient, corrosion-resistant solutions for repair of existing pipelines.

For offshore oil and gas pipelines, in recent years, companies such as Strohm B.V. (formerly Airborne Oil & Gas, Ijmuiden, Netherlands) and Magma Global Ltd. (Portsmouth, U.K.) have led the way toward development and qualification of thermoplastic composite pipe (TCP) to replace metal in offshore pipelines. Strohm announced DNV qualification of its deepwater TCP flowline/jumper technology in November 2023, followed by multiple announcements of installations and new contracts in 2024. In early 2025, the company reported a new MOU with subsea connections systems provider Unitech Offshore (Stord, Norway) for the development of an end-to-end subsea jumper connection solution that is simpler to install and also flange-less through integration with Strohm’s TCP end fittings. The company also launched TCP Designer, a web-based tool enabling customers to more quickly and easily engineer customized TCPs.

TCP for hydrogen transport

Companies are also adapting TCP for transportation of hydrogen. For example, in February 2024, Strohm announced that it had completed a hydrogen testing program with its TCPs at Tüv-Süd in Germany.

Hive’s TCP is designed specifically to meet hydrogen permeation requirements while also minimizing its carbon footprint. Source | Hive Composites

Hive Composites (Loughborough, U.K.) is an example of a company that has developed a TCP system specifically for hydrogen applications. As reported by CW’s Stewart Mitchell, Hive Composites’ TCP system is manufactured from high-density polyethylene (HDPE) for both the inner and outer layers, augmented with glass fiber-reinforced polymer (GFRP) and other specialized barrier materials. It can be manufactured in continuous lengths of up to 1.2 kilometers, with diameters from 2-6 inches, and are designed to operate at pressures up to 100 bar.

Hive Composites claims the global warming potential of TCP is more than four times lower than that of equivalent steel pipes in terms of materials, manufacturing and transport, and the operational and decommissioning emissions of TCP are approximately 60-70% lower.

CMC to enable nuclear fusion

According to the IEA, more than 7 GW of nuclear power capacity was brought online in 2024, a 33% increase over 2023.

There is increasing interest in the use of CMC for components in nuclear power plants, especially to meet the high-temperature needs of next-generation fusion reactors in development. “Although power from nuclear fusion is many decades away, its potential is huge, offering four times more energy per kilogram of fuel than fission (current nuclear power plants) and nearly four million times more energy than burning oil or coal — but without any carbon emissions,” explains CW’s Ginger Gardiner (see “Composites reinvent energy”).

For example, the National Composites Centre (NCC, Bristol, U.K.) is developing silicon carbide CMC (SiC/SiC) for applications in future fusion reactors. SiC/SiC materials are reported to be damage-tolerant, resistant to radiation and have operating temperatures of up to 1600°C, and their use is expected to enable fusion reactors to operate at higher temperatures to improve thermal efficiency, in turn increasing commercial viability.

The NCC announced in 2023 that it is lending its expertise in this area to the HASTE-F program led by the UK Atomic Energy Authority (UKEA, Abingdon), with goals of working toward scalability, formability and performance in manufacturing SiC/SiC reactor components.

The fuel rod cladding, reactor core and core structures in advanced nuclear reactors are manufactured from GA-EMS’ SiGA, a high-tech CMC that can withstand more than twice the temperature of metal components used in current reactors. Source | General Atomics Advanced Reactors and U.S. DOE Office of Nuclear Energy

In the U.S., General Atomics Electromagnetic Systems (GA-EMS, San Diego, Calif.) is also developing SiC materials as well as SiC composite foam for nuclear fuel rod cladding and other applications in fusion plants. In 2024, the company was awarded a 3-year contract from the U.S. DOE Office of Science to develop a scalable, cost-competitive manufacturing path for these materials.

GA-EMS reports that its SiGA high-tech engineered CMC can be fabricated into complex planar, tubular and custom geometries, and that finished SiGA composites maintain their strength and stability under high levels of irradiation up to temperatures well above 1600°C.

In October 2024, GA-EMS announced that it had achieved a project milestone with the preliminary development of four digital twin performance models to support its technology and accelerate the process of qualification and licensing. In December 2024, the company reported successful first-round testing of its SiGA fuel rod samples at Idaho National Laboratory (INL, Idaho Falls, U.S.).

In addition, CW’s Gardiner has reported about BJS Ceramics and BJS Composites (Gersthofen, Germany), a company that makes its own SiC fiber, branded Silafil, and infiltrates that and carbon fiber with Silafil pre-ceramic polymer as a matrix to create Keraman CMC materials and parts.

BJS co-founder Jutta Schull says that the company has seen increased demand in the aerospace and defense sectors, but also for cooling pump applications in nuclear fission and fusion plants. Schull explains, “Due to their thermal resistance, high damage tolerance and radiation resistance, SiC/SiC components can double the electricity generation from fusion reactors — according to findings of our customers.”

While nuclear fusion reactors may still have a ways to go in the coming years, the benefits of composite materials are, and will continue to be, a key enabler for nuclear, renewable and traditional oil and gas energy applications.

Related Content

The future of quartz and oxide fibers at Saint-Gobain Advanced Ceramic Composites

New business builds on 100-year legacy in quartz, prepares for growth, while starting production of oxide fibers to meet increased demand for CMC by aerospace and industrial sectors.

Read MoreA new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MoreComposites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MoreBio-based, fire-resistant composites become mainstream

Projects use Duplicor prepreg panels with highest Euroclass B fire performance without fire retardants for reduced weight, CO2 footprint in sustainable yet affordable roofs, high-rise façades and modular housing.

Read MoreRead Next

Thermoplastic composite pipes provide 59% reduction in H2 distribution CO2 emissions

Hive Composites’ multilayer thermoplastic composite pipe (TPC) design meets hydrogen permeation requirements while ensuring substantial CO2 reductions compared to conventional steel pipe systems.

Read MoreGWEC launches 2025 global wind report

Despite a year of headwinds, 2024 still enjoyed another record year of wind energy installation globally. Even so, the Global Wind Energy Council report offers a data-led roadmap to triple growth and meet COP28 targets.

Read MoreUltra-thin woven fabric enables 90% resource reduction in satellite solar array manufacturing

Kerberos Engineering uses TeXtreme 0/90 woven fabrics for satellite solar array manufacturing, cutting weight and onboard resources, enhancing structural integrity and streamlining production.

Read More

.jpg;width=70;height=70;mode=crop)