D-STANDART project advances durability modeling of large-scale composite structures

D-STANDART is developing rapid methods to better characterize fatigue damage under real conditions for composites and supply chain sustainability. Results will be presented at JEC World 2025.

Share

Read Next

Double cantilever beam (DCB) test to characterize delamination growth under fatigue loading. Source | TU Delft

D-STANDARD, a 36-month EU-funded project developing a novel approach to fatigue characterization of large-scale composite structures, has shared preliminary results since the project’s start in January 2023.

Ensuring that a composite structure will function during its entire service life requires a thorough durability evaluation, including the effect of fatigue loading. At the same time, design features that increase durability typically result in higher reserve factors, such as less efficient material use. What is therefore needed is an evaluation of the product’s expected fatigue performance, and an understanding of the life cycle impact of different design choices at an early enough design stage that changes can still be implemented relatively cheaply.

D-STANDART is addressing this need. The project team started this process with novel experimental fatigue characterization methods, using this data to validate high fidelity models. These models are then used to create a synthetic dataset which is used in the training of an AI-enabled surrogate model. This surrogate model captures the material complexity of composite laminates, but runs cheaply enough that it can be incorporated into industrial design analyses of full-scale structures. At the same time, a new coefficient-based life cycle assessment (LCA) model strikes a balance between accuracy and the need to have already mapped out all process details.

D-STANDART is led by the Netherlands Aerospace Centre (NLR) and involves thirteen partners — three universities, two research centers, six industrial companies and two SMEs from seven countries (Belgium, France, Germany, Italy, the Netherlands, Spain and the U.K.):

- University of Bristol

- University of Twente

- Delft University of Technology (TU Delft)

- Royal Netherlands Aerospace Center

- National Composites Centre (NCC)

- SE Blades Technology B.V.

- Five entites of MSC Software from Hexagon Group

- ICOMAT Ltd.

- L-UP SAS

The project started in 2023, and is now entering its last year, with final results expected to be presented around the holiday period.

Some preliminary results have been shared below:

- A high-frequency test method has been developed that allows characterizing fatigue onset performance within days instead of weeks. This will be further commercialized by startup company XCTE.

- Existing practices for characterization of fatigue delamination growth have been modified to also capture the effect of fiber orientation in multidirectional laminates, better characterizing the effect of different layups on fatigue performance.

- Lessons learned from D-STANDART have provided input to the CEN Workshop Agreement 17815 on material characterization terminology and structured documentation (cwa17815_2025).

- High fidelity models developed within DSTANDART show a good agreement between prediction and experiment, in terms of damage progression and stiffness degradation, when modeling the behavior of complex features such as wrinkles and ply-drops.

- The developed LCA model can inform sector-specific trade-offs of design life extension versus increased manufacturing impact.

During the final year of the project D-STANDART aims to fully develop the surrogate modeling approach and validate it on a structural element level.

The D-STANDART team is eager for feedback from the composites’ community, and will be available to meet at JEC World 2025 (Booth D114-02, Hall 6). On March 5th, the consortium also offers a series of free training workshops and panel discussions, which can also be followed online.

Visit the project website to contact the team, and stay up to date with all project results.

Funded by the European Union under GA n° 101091409. Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union. Neither the European Union nor the granting authority can be held responsible for them.

Related Content

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MoreASCEND program completion: Transforming the U.K.'s high-rate composites manufacturing capability

GKN Aerospace, McLaren Automotive and U.K. partners chart the final chapter of the 4-year, £39.6 million ASCEND program, which accomplished significant progress in high-rate production, Industry 4.0 and sustainable composites manufacturing.

Read MoreAurora reveals latest SPRINT X-Plane design concept

An Aurora and Boeing team advances its high-speed, vertical lift concept to the preliminary design phase, which features three lift fans, a more refined composite exterior and an uncrewed cockpit.

Read MoreCarbon fiber/flax landing gear achieves 54% weight reduction via tailored layup optimization

Fuko’s Biogear showcases how strategic composite material distribution and natural fiber damping properties can lightweight and enhance critical aerospace structure performance.

Read MoreRead Next

MORPHO advances structural prognostics, health monitoring and composites manufacturing efficiencies

EU project concluded in January 2025, delivering on its goals to enhance aerospace industry performance and sustainability through real-time monitoring, intelligent control systems and innovative recycling techniques.

Read MoreWe4Ce infused 2.5-3-MW rotor blade design passes validation test

Composite rotor blade structure design by We4Ce, mold and prototype production by InDutch Composites and fatigue testing by Suzlon Group has resulted in the novel blade’s IEC61400-5:2020 certification.

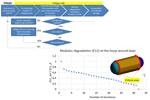

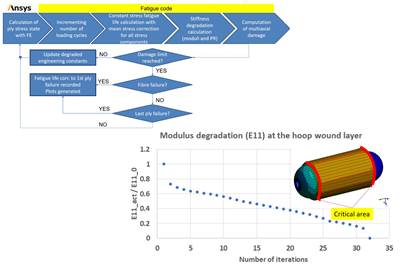

Read MoreNumerical tool with mean stress correction demonstrated for fatigue life estimation of thermoplastic composites

To aid design of fatigue-resistant structures, Econ Engineering has developed an algorithm to evaluate ply-based cyclic stiffness degradation combined with an FE failure check, validated for a CF/PAEK pressure vessel.

Read More