Ginger Gardiner Senior Technical Editor

Ginger Gardiner, Senior Technical Editor at CompositesWorld, began writing for the magazine in 2006 and was hired as Senior Editor in 2013. She is a co-author of the textbook Essentials of Advanced Composite Fabrication & Repair. Ginger has a degree in mechanical engineering from Rice University and began her career in technical marketing at DuPont’s Composites Division for KEVLAR and NOMEX products in aerospace and marine structures. PRESS KIT

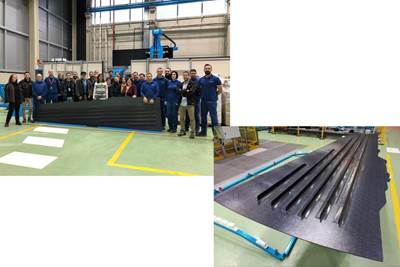

CIRA qualifies CMC structures for the reusable Space Rider

Italian team designs, builds and tests multiple large, complex thermal protection system structures made from patented ISiComp C/C-SiC ceramic matrix composites.

WatchAdvancing thermoplastic composite primary structure and morphing wings

The HERWINGT project in Clean Aviation seeks to ready technologies — including at least 16 composite demonstrators — for a hybrid-electric regional aircraft with 50% less fuel burn to be launched by 2035.

WatchThe new Slate truck costs less than $20,000, uses PP composite body panels

Stylish vehicle EV pickup model is supported by a simplified manufacturing process. It is also capable of customization from two seats to five seats.

WatchClean Hydrogen Partnership announces 26 new projects

Awarding €154.6 million in grants, the Clean Hydrogen Joint Undertaking aims to accelerate development and deployment of hydrogen technologies across Europe.

Read MoreNear-zero erosion ultra-high temperature CMC

K3RX commercializes UHTCMC for a wide range of markets, demonstrating performance in prototypes, assemblies and advancing manufacturing to reduce cost.

Read MoreComposites end markets: Aviation and advanced air mobility (2025)

Despite persistent supply chain issues, markets were set for healthy growth before Trump policies and tariffs, yet long-term trends favor composites in new platforms. Meanwhile, advanced air mobility shakes out and moves forward.

WatchThe AAMMC Tech Hub: Ramping U.S. production of large thermoplastic composite aerostructures

CW talks with Syensqo, Spirit AeroSystems and other consortia members about current funding, specification of the next world’s largest press, organizational structure and projects to support U.S. companies in the race to deliver >40,000 sustainable and efficient aircraft over the next 20 years.

Read MoreJEC World 2025 highlights: New thermoplastics, PI fiber, solutions for FR, machining, digitized processes and more

CW senior technical editor Ginger Gardiner discusses latest developments in composites from this year’s show.

WatchPlasma moves beyond improved bonding to coatings, multifunctional composites

Plasmatreat cold plasma systems clean, activate surfaces and apply nanocoatings for dielectric barriers and more.

WatchNatilus begins search for Phase I and II production sites for composite blended wing body aircraft

With more than 570 pre-orders for its Kona cargo and Horizon passenger aircraft, Natilus begins discussions with sites and suppliers in the U.S. for its 250,000-square-foot Phase I facility and also in the UAE, India and Saudi Arabia for its Phase II expansion.

Read MorePlant tour: Collins Aerospace, Riverside, Calif., U.S. and Almere, Netherlands

Composite Tier 1’s long history, acquisition of stamped parts pioneer Dutch Thermoplastic Components, advances roadmap for growth in thermoplastic composite parts.

Read MoreVIDEO: Installing the world’s largest thermoplastic composites press at Airbus Bremen

At JEC World 2025, Pinette PEI detailed its latest turnkey system for future aircraft serial parts production.

Watch