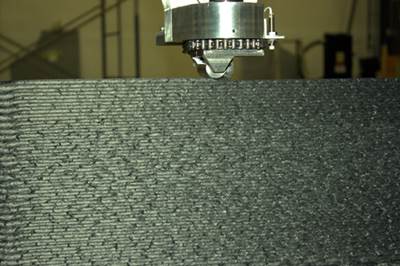

Large-scale machine demonstrates composites AM capabilities

CAMX 2024: Thermwood Corp. is demonstrating several AM technology solutions through the LSAM AP 510 system and cut layer additive (CLA) process.

Share

Thermwood (Dale, Ind., U.S.) is exhibiting its additive manufacturing (AM) technology solutions through the demonstration of its LSAM AP 510 system and cut layer additive (CLA) system. Product features for the former include:

- Autoclave tools for aerospace composite layups, which are reported to enhance composites manufacturing processes with high-precision, reliable tools.

- Trim fixtures, said to improve efficiency in a users’ manufacturing workflow.

The company’s LSAM Additive Printer systems are single-gantry, moving table configurations and are available in two table sizes: 5' × 5' and 5' × 10'. The 5' × 10' table is available in two configurations, 5' wide with 10' of front to back motion, and 10' wide with 5' of front-to-back motion. Choice of configuration depends on several factors; fitting it existing factory floor space is one example.

The highly rigid tab and slot structural steel gantry also incorporates a fume extraction system that pulls print fumes through specially designed activated charcoal filters to remove them and “sweeten” the air.

LSAM Additive Printers use the exact same print head mechanism as all the others, including Thermwood’s largest LSAM systems, which means that they produce the same high print quality. They also use the same highly advanced Ultra 6 control with all its exclusive, patented print features and capabilities.

The systems come standard with a single hopper polymer dryer for applications that don’t change print material very often. For installations that print a wider variety of materials, a dual hopper dryer is available as an option.

An enclosure that surrounds the machine is also available. The machine with the full enclosure can also be built to meet European CE standards.

Thermwood is also demonstrating several tools from its CLA system, which can enable users to create large-format additive tools from materials that are unable to be printed.

The company’s team of AM representatives are available to discuss customers’ specific needs and provide detailed insights into the company’s technology and its applications.

Related Content

-

Orbital Composites wins AFWERX award for Starfighter drone fleet

Under the TACFI contract, Orbital is implementing the AMCM process to build 3D printed composite multi-mission UAS aircraft, surpassing $10 million in government awards.

-

3D-printed CFRP tools for serial production of composite landing flaps

GKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.

-

The next evolution in AFP

Automated fiber placement develops into more compact, flexible, modular and digitized systems with multi-material and process capabilities.

Related Content

Orbital Composites wins AFWERX award for Starfighter drone fleet

Under the TACFI contract, Orbital is implementing the AMCM process to build 3D printed composite multi-mission UAS aircraft, surpassing $10 million in government awards.

Read More3D-printed CFRP tools for serial production of composite landing flaps

GKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.

Read MoreThe next evolution in AFP

Automated fiber placement develops into more compact, flexible, modular and digitized systems with multi-material and process capabilities.

Read MoreAl Seer Marine, Abu Dhabi Maritime unveil world’s largest 3D-printed boat

Holding the new Guinness World Record at 11.98 meters, the 3D-printed composite water taxi used a CEAD Flexbot to print two hulls in less than 12 days.

Read MoreRead Next

Thermwood developing large-scale additive manufacturing system

The large-format additive manufacturing machine will produce near net shape parts up to 10 by 10 by 5 ft and provide post-process machining and trimming functions as well.

Read MoreThermwood’s vertical layer printing turns AM on its side

Vertical Layer Printing (VLP) 3D prints layers perpendicular to the floor, extending Z height to the length of the print bed — as long as 40 feet.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More