MiniLab consortium produces first full-scale thermoplastic composite hydrofoils

Project advances toward first recyclable foils for ocean racing, part of “Infinite Foil” finalist for JEC Innovation Award 2025.

Victrex and MiniLab members beside the developed thermoplastic composite (TPC) hydrofoils. Source (All Images) | Avel Robotics, MiniLab

MiniLab is an open innovation ecosystem that connects public and private partners around full-scale demonstrator projects to develop and test technologies. The platform was founded in 2023 by Adrien Marchandise, co-founder and CTO of Avel Robotics (Lorient, France) to advance sustainability and reduce the sailing industry’s environmental impact.

Infinite Foil is one of MiniLab’s first projects, aimed to demonstrate the first recyclable composite hydrofoils for ocean racing (read “Breton companies launch recyclable hydrofoil design project”). This initial foil is sized for MiniLab’s in-situ testing lab — a Mini 6.5-meter regatta sailing vessel. Multiple foils will be produced and raced during the 2025 regatta season.

Infinite Foil project partners include:

- Avel Robotics (Lorient, France) — Designs and produces carbin fiber-reinforced polymer (CFRP) hydrofoils using automated fiber placement (AFP)

- ComposiTIC (Ploemeur, France) and IRMA (Lorient, France) — Technical innovation centers focused on polymers, composites, robotic AFP and additive manufacturing

- Diab (Helsingborg, Sweden) — Recycled and recyclable PET foam supplier

- Victrex — Supplier of LMPAEK polymer for high-performance thermoplastic composite (TPC) prepreg tape.

With the combined know-how of these partners, MiniLab has produced its first TPC hydrofoil on a scale representative of production parts. This demonstrator validates multiple elements:

- Required radius of curvature and accuracy of dimensions

- Best draping strategies and parameters for robotic AFP layup

- Ability to analyze and optimize the consolidation and molding process.

The finished part was then tested to measure the mechanical properties.

According to Marchandise, the 2025 program for the TPC hydrofoil includes:

- Integration of fiber optic sensors by partner Pixel sur Mer (Lorient, France) to measure the level of strain LMPAEK can reach in extreme conditions without damage

- Acoustic emission sensors will be integrated by MiniLab in order to monitor in situ the potential damages the foil will encounter

- Mechanical testing of the foils via Southern Brittany University (Université Bretagne-Sud) bench test to validate elastic characteristic and to calibrate the sensors

First seal trials are expected in February of this year in Lorient, followed by first initial offshore qualification races between April and June. The definitive validation of the robustness of this material will be provided by Mini Transat 2025 starting Sept. 21, 2025, a single-handed ocean race across the Atlantic Ocean covering 4,000 miles.

Industry will be able to see the TPC hydrofoils in person at Avel’s booth at JEC 2025, as well as at one of the JEC Planets. “We’re looking for new sponsors to book the year’s budget to participate in the Mini Transat 2025,” Marchandise says.

In parallel with Infinite Foil, Avel Robotics has launched a larger foil project funded by the Region Bretagne with a new partner, Mer Concept (Brittany), that has just won the Vendée Globe for its IMOCA MACIF Santé Prévoyance, an IMOCA 60 monohull sailing yacht. “We’re going to develop a thermoplastic material with improved compressive strength,” says Marchandise. “Our goal is to start the scale up to industrialize thermoplastic composite foils for larger sailing vessels, and we hope to manufacture the first such foils for ULTIM or IMOCA class racing yachts in 2026/2027.” Each week through February 2025, Marchandise’ team will share a key stage of this technical and collaborative work.

For more details, see CW’s description of MiniLab in: “Composites End Markets: Boatbuilding and Marine (2025).” Those interested in the TPC hydrofoil project should follow MiniLab on LinkedIn and visit the “Infinite Foil” project at JEC2025, where it was a finalist for this year’s Composites Innovation Award.

Related Content

Composites end markets: Boatbuilding and marine (2025)

As 2023-2024 consumer demand slows, boat and marine vessel manufacturers continue to focus on decarbonization and new technologies using composites.

Read MoreThe lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

Read MoreFIDAMC expands composites R&D into new markets and advanced manufacturing centers

Pioneering technocenter advances RTM, thermoplastic composites, additive manufacturing, microwire, novel lighter weight LSP and more.

Read MoreAnemoi installs 35-meter-tall composite rotor sails on Sohar Max maritime vessel

Carbon fiber-reinforced epoxy composites are key to building these long-lasting wind propulsion technologies for energy-efficient watercraft.

Read MoreRead Next

Candela C-8 hydrofoil boat marks record trip across the Baltic

The electric vessel, claimed to be the first to cross the Baltic Sea, cuts traditional refueling needs in half, achieves 95% less operating costs, during the 150-nautical-mile journey.

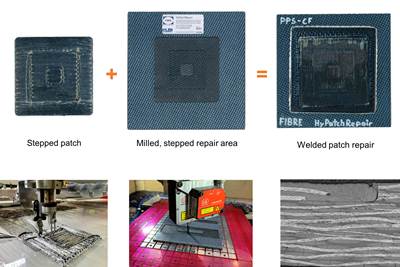

Read MoreDeveloping repairs for thermoplastic composite aerostructures

HyPatchRepair project proves feasibility of automated process chain for welded thermoplastic composite patch repairs.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More