Modular AFP automation family supports adaptable production handling

CAMX 2024: Broetje-Automation’s Staxx family of AFP solutions create an ecosystem of functionality, versatility and scalable automation.

Share

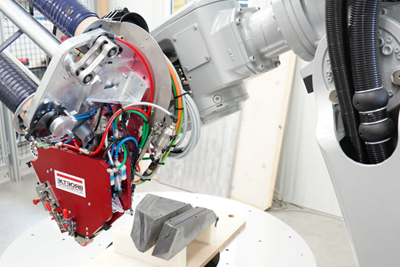

Broetje-Automation (Rastede, Germany) announces solutions for smart automated fiber placement (AFP) automation — from prototype to large-scale production. The star of the show, the Staxx One, is a transportable AFP cell designed for simple, plug-and-play handling. Demonstrations take place twice a day, highlighting the system’s various functions, versatility and scalable automation.

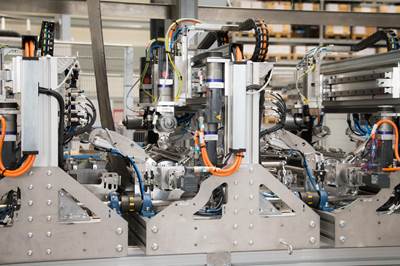

From the highly compact and cost-effective Staxx Box to the high-performance capabilities of the 16-tow robotic Staxx Flex system, each member of the Staxx family represents one specific building block to form an ecosystem of modular AFP automation.

The Staxx Box is designed for layup tests, material qualification and small parts, while the Staxx One single-tow robotic system can add additional flexibility — it can be mounted on an industrial robot while using the same AFP end effector as the Staxx Box. The large, 16-tow AFP system, Staxx Flex, is designed for layup of complex and large structures, while the Staxx Compact focuses on high-rate production capabilities.

The Staxx family shares many system components due to its modular design and an integrated software backbone. Therefore, a wide range of different fiber placement applications and materials are covered to serve the individual needs of each customer. Through the AFP systems’ Factory of the Future focus, Staxx targets AFP optimization through enhanced precision, efficiency and reliability for composites manufacturing.

Related Content

-

CAMX 2023 exhibit preview compilation, Part 1

Prepare for CAMX 2023 in Atlanta with this list of 60+ exhibitor previews received by CW, highlighting key technologies, services and trends available to attendees.

-

VIDEO: Flexible molding and machining for composites

Addcomp and bespline are sister companies that offer innovative solutions for composites. This video from CAMX 2024 offers an overview of Addcomp’s AFP solutions.

-

Graphene-enhanced SMC boosts molded component properties

CAMX 2023: Commercially sold GrapheneBlack SMC from NanoXplore increases part strength, stiffness and provides other benefits for transportation, renewable energy, energy storage and industrial markets.

Related Content

CAMX 2023 exhibit preview compilation, Part 1

Prepare for CAMX 2023 in Atlanta with this list of 60+ exhibitor previews received by CW, highlighting key technologies, services and trends available to attendees.

Read MoreVIDEO: Flexible molding and machining for composites

Addcomp and bespline are sister companies that offer innovative solutions for composites. This video from CAMX 2024 offers an overview of Addcomp’s AFP solutions.

Read MoreGraphene-enhanced SMC boosts molded component properties

CAMX 2023: Commercially sold GrapheneBlack SMC from NanoXplore increases part strength, stiffness and provides other benefits for transportation, renewable energy, energy storage and industrial markets.

Read MoreVIDEO: Robots enable nine-axis machining of composites

Machine Tool Camp displayed its hybrid machining center at CAMX, featuring nine-axis machining capability enabled by robotics.

Read MoreRead Next

Broetje-Automation, Spirit complete CCPS project for automating aircraft preform production

Continuous composite preforming system (CCPS) integrates all work steps, from the roll to the stringer, in a fully automated, smaller footprint process, taking the next step for future aircraft programs.

Read MoreBroetje-Automation demonstrates rCF placement via AFP

Through the ScrapSeRO project, the system integrator and machine builder successfully processed recycled composites, in addition to more traditional materials, via its highly flexible Staxx One system.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More