Universal test system, testing fixtures provide standardized composites testing

CAMX 2024: MTS Systems showcases the Criterion 43 universal test system with a custom software interface, as well as composites testing fixtures and contact and noncontact extensometers.

Share

MTS Systems Corp. (Eden Prairie, Minn., U.S.) is providing a glimpse of its latest innovations in composite materials testing, such as testing fixtures and the company’s MTS Criterion family.

Designed for ease of operation, adherence to worldwide safety and ergonomic directives, and a multi-language MTS TestSuite TW software interface, the MTS Criterion family acts as a foundation for establishing and sustaining global, standardized test procedures.

The Criterion 43 universal test system comes complete with grips and an extensometer. The system features advanced controller technology, with a data acquisition rate of up to 5,000 Hz, which is said to be five times faster than the company’s previous controller. This improvement enables more precise measurement during a test and can be valuable when testing brittle or composite materials. An update rate of 5,000 Hz is also capable of providing improved measurement control for stiff specimens. In addition, cascade control is integrated into all MTS Criterion Systems, providing load and strain control as well as displacement control.

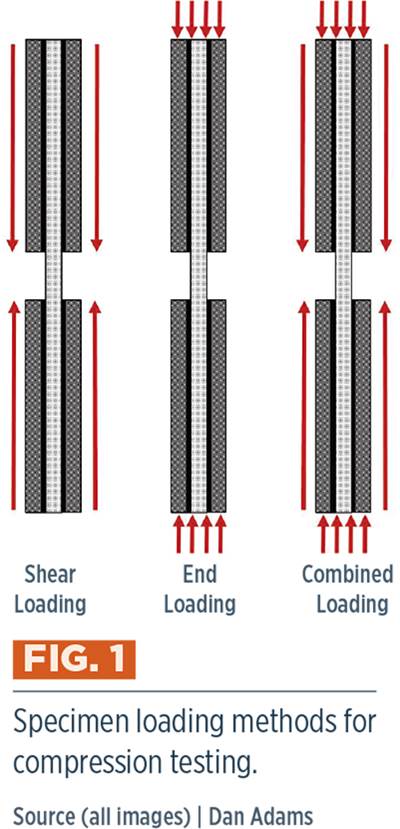

MTS is also sharing information about a wide array of composites testing fixtures, such as the following options designed for compression testing: the combined loading compression (CLC) composite fixture for testing per ASTM D6641; the modified celanese compression loading composite fixture for testing per ISO 14126; method 1 option A or the IITRI compression loading composite fixture for testing per ASTM D3410; and ISO 14126 method 1 option B.

Additionally, MTS is highlighting contacting and noncontact extensometers, including the MTS Advantage Video Extensometer (AVX). The AVX is designed to deliver the flexibility, accuracy and repeatability needed in applications where it is difficult to measure strain using conventional means. This video extensometer combines several features for measuring axial and transverse strain on composites.

MTS experts can provide more information about these products or any MTS solutions for dynamic testing, including the MTS Acumen electrodynamic test system, MTS Landmark and Servohydraulic test system, plus, its high-rate, high-force, axial-torsional and planar biaxial test systems.

Related Content

-

CAMX 2023 exhibit preview compilation, Part 1

Prepare for CAMX 2023 in Atlanta with this list of 60+ exhibitor previews received by CW, highlighting key technologies, services and trends available to attendees.

-

CAMX 2023 exhibit preview compilation, Part 2

Part 2 continues to showcase the materials, services, machinery, live demonstrations and other innovations presented by CAMX 2023 exhibitors.

-

VIDEO: Recycling and machining carbon fiber scraps

Elevated Materials has partnered with Toray Composite Materials America, Inc. to collect and upcycle reclaimed carbon fiber scraps into large billet laminates, which can then be cut into various parts using CNC mills.

Related Content

CAMX 2023 exhibit preview compilation, Part 1

Prepare for CAMX 2023 in Atlanta with this list of 60+ exhibitor previews received by CW, highlighting key technologies, services and trends available to attendees.

Read MoreCAMX 2023 exhibit preview compilation, Part 2

Part 2 continues to showcase the materials, services, machinery, live demonstrations and other innovations presented by CAMX 2023 exhibitors.

Read MoreVIDEO: Recycling and machining carbon fiber scraps

Elevated Materials has partnered with Toray Composite Materials America, Inc. to collect and upcycle reclaimed carbon fiber scraps into large billet laminates, which can then be cut into various parts using CNC mills.

Read MoreNew brand identity launch aligns with nonwoven portfolio offerings

CAMX 2024: James Cropper, formerly known as Technical Fibre Products, is bringing its new name to the U.S. composites industry, highlighting its specialization in carrier, surface and fire protection veils, among other products.

Read MoreRead Next

Instron introduces 3400 and 6800 Series universal testing systems

New high-force floor models range up to 300-kilonewton force capacity, with a host of new features covering user safety, comfort, repeatability and long-lasting service life.

Read MoreOptimum unidirectional compression testing of composites

Dr. Daniel O. Adams, a professor of mechanical engineering, the director of the Composite Mechanics Laboratory at the University of Utah, and VP of Wyoming Test Fixtures Inc. (Salt Lake City, UT, US) discusses the complex relationship between composite tensile and compressive properties, why that makes it necessary to perform both tension and compression testing, and how best to perform the latter.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More