Latest Aerospace Articles

VIEW ALLJekta begins flight testing of scaled PHA-ZE 100 amphibious aircraft

Trials of 1:9 scaled composite prototype marks new milestones in the program’s development, including plans to introduce the new aircraft globally in 2030.

Read MoreDeutsche Aircraft rolls out D328eco test aircraft

The D328eco turboprop is an advanced evolution of the Dornier 328 with advanced features and a composites-intensive design. Its flight campaign is expected to begin soon.

Read MoreAirbus completes first A350F wingset in Broughton

The wingset was formed as part of the company’s first A350 freighter test aircraft, set to serve the highly anticipated demand in passenger and freight markets.

Read MoreHartzell’s carbon fiber Pathfinder is approved for Aviat Husky

Three-blade composite propeller has received supplemental type certification and can replace existing two-bladed propellers on Husky aircraft models.

Read MoreVivace delivers fuel tank hardware for Talon-A test vehicles

In its partnership with Stratolaunch to advance U.S. hypersonic capabilities, Vivace has provided both composite and metal tanks for the TA-1 and TA-2 in the past year.

Read MoreAerospace manufacturing innovations demonstrate the future of aerocomposites

CAMX 2025: Attendees are able to explore several of NIAR ATLAS’ prototype developments in person, highlighting tool-less space manufacturing, AI-enabled inspection and repair and thermoplastic overmolding.

Read MoreKnowledge Centers

During CW Tech Days: Thermoplastics for Large Structures, experts explored the materials and processing technologies that are enabling the transition to large-part manufacturing.

LEARN MORELatest Aerospace News And Updates

Wichita State, Dassault Systèmes open Manufacturing Innovation Center

Aviation companies of all sizes will be able to improve their resilience and efficiency via the center’s virtual design, automation and additive manufacturing capabilities.

Read MoreAgile Ultrasonics breaks new ground for ultrasonic composites welding in space manufacturing

Continuous ultrasonic welding (CUW) innovation presents the flexibility crucial for future lunar and deep-space missions, but also for composites joining in defense and commercial aerospace.

Read MoreFlyber launches U.K. composites manufacturing site for advanced mobility applications

The startup’s design automation and composite material layup and curing technologies target lightweighting for aerospace, UAVs, eVTOL and high-performance mobility platforms.

Read MoreBoeing announces historic widebody aircraft order from Qatar Airways

Agreement for 210 airplanes sets a record for Boeing, in addition to it being the Middle Eastern airliner’s largest order of 787 Dreamliners.

Read MoreHexcel, Specialty Materials launch boron fiber-infused high modulus carbon fiber

High-compression, hybridized unidirectional prepreg targets advanced commercial and military application opportunities.

Read MoreSyensqo composites demonstrate titanium replacement on Boeing MQ-25 Stingray

Validation of integrating Cycom 5250-4HT prepreg into the UAV’s exhaust nozzle structure underpins the material system’s use in other high-temperature aerospace applications.

Read MoreFeatured Posts

Prepreg compression molding supports higher-rate propeller manufacturing

To meet increasing UAV market demands, Mejzlik Propellers has added a higher-rate compression molding line to its custom CFRP propeller capabilities.

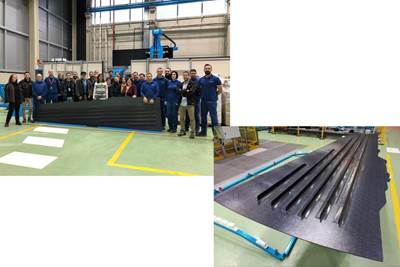

WatchCIRA qualifies CMC structures for the reusable Space Rider

Italian team designs, builds and tests multiple large, complex thermal protection system structures made from patented ISiComp C/C-SiC ceramic matrix composites.

WatchAdvancing thermoplastic composite primary structure and morphing wings

The HERWINGT project in Clean Aviation seeks to ready technologies — including at least 16 composite demonstrators — for a hybrid-electric regional aircraft with 50% less fuel burn to be launched by 2035.

WatchThere's a lot up in the air

Trade tensions and supply chain shifts — what the U.S.-China dispute means for aerospace and composites suppliers.

Read MoreNear-zero erosion ultra-high temperature CMC

K3RX commercializes UHTCMC for a wide range of markets, demonstrating performance in prototypes, assemblies and advancing manufacturing to reduce cost.

Read MoreComposites end markets: Aviation and advanced air mobility (2025)

Despite persistent supply chain issues, markets were set for healthy growth before Trump policies and tariffs, yet long-term trends favor composites in new platforms. Meanwhile, advanced air mobility shakes out and moves forward.

WatchFAQ: Aerospace

How are composites used in aerospace structures?

Since the 1950s*, composites have been growing in use in commercial and defense aircraft, ranging from struts and tail components, to wing skins and fuselages, to engine components and propeller blades.

One of the largest challenges to adoption of composites by the aerospace industry is stringent standards especially for safety critical structures, necessitating time- and labor-intensive processes to qualify new materials for use on passenger aircraft.

Qualified and well-tested autoclave-cured carbon fiber and thermoset-based prepregs are most often used for many structures, though other materials and formats, including thermoplastic tapes, are also in development or use.

Source: The FAA: Keeping up with aerocomposites evolution

*In the 1950s, Boeing began using fiberglass in its 707 passenger jets, and at the time the material made up about 2% of the overall aircraft by weight. Since then, Boeing, Airbus and other aircraft manufacturers have continued to increase this percentage with successive aircraft models. Today’s twin-aisle commercial aircraft such as the Boeing 787, first launched in 2009, and the Airbus A350 comprise approximately 50% composites by weight, largely carbon fiber-reinforced polymer (CFRP).

How are composites used in space structures?

At the time the Apollo capsule, which landed on the moon in 1969, was built by NASA, composites industry was still in its infancy and the materials were not yet in widespread use, though the Apollo capsule used early composite technology in the form of an ablative heat shield made from Avcoat, an epoxy novolac resin with silica fibers in a fiberglass-phenolic honeycomb matrix. A fiberglass honeycomb was bonded to the primary structure and the paste-like material was injected into each cell individually.

Since Apollo, advanced composites have evolved by leaps and bounds, and have played a significant role in space programs with use in launch vehicles, the space shuttle, satellites, space telescopes and the International Space Station.

Source: Composites in the race to space