Thermoplastics

Thermoplastics play a pivotal role in composite materials by serving as the matrix phase that binds reinforcements together. Unlike thermoset resins, thermoplastics possess the ability to soften and reform when heated, allowing for reshaping and recycling. They offer unique advantages such as high toughness, chemical resistance, and easy processing, making them versatile in various industries like aerospace, automotive, and consumer goods. Composites using thermoplastic matrices exhibit exceptional damage tolerance and are sought after for their potential in complex manufacturing processes like injection molding, enabling efficient production of intricate and high-performance parts.

Latest Thermoplastics Articles

VIEW ALLAerospace manufacturing innovations demonstrate the future of aerocomposites

CAMX 2025: Attendees are able to explore several of NIAR ATLAS’ prototype developments in person, highlighting tool-less space manufacturing, AI-enabled inspection and repair and thermoplastic overmolding.

Read MoreThe AMRC announces U.K. open-access TPC tape development

Dedicated research platform, available to businesses and researchers at the AMRC’s Factory of the Future facility, features Cygnet Texkimp’s hybrid line and tape slitter on a pilot scale.

Read MoreXenia presents Xeramic ceramic thermoplastic fillers

Compounds range, available in the Pure version and the fiber-reinforced Core version, are an addition to Xenia’s product solutions featuring high thermal conductivity and heat dissipation.

Read MoreHRC highlights automotive material innovation, scalable manufacturing and sustainable systems

The composites company is meeting the transition to electrification and vehicle lightweighting via hybrid monocoques, use of thermoplastic composites and carbon fiber and recycling.

Read MoreOligomer polymer engineering transforms 100% recyclable thermoplastic composite paradigms

MET-OL thermoplastic technology alters high molecular weight polybutylene terephthalate into low-viscosity oligomers, enhancing fiber impregnation and catalytic repolymerization for fully recyclable, high-performance composites.

Read MoreThe new Slate truck costs less than $20,000, uses PP composite body panels

Stylish vehicle EV pickup model is supported by a simplified manufacturing process. It is also capable of customization from two seats to five seats.

WatchKnowledge Centers

CW’s editors are tracking the latest trends and developments in tooling, from the basics to new developments. This collection, presented by Composites One, features four recent CW stories that detail a range of tooling technologies, processes and materials.

LEARN MORE

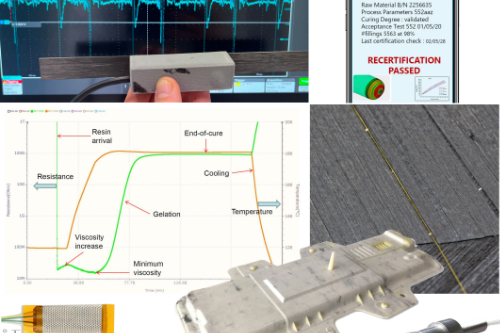

Discover the types of sensors being used in composites, the physics on which they�re based, their installation, promised benefits and challenges, as well as the potential they offer for even further developments in smart structures.

LEARN MORE

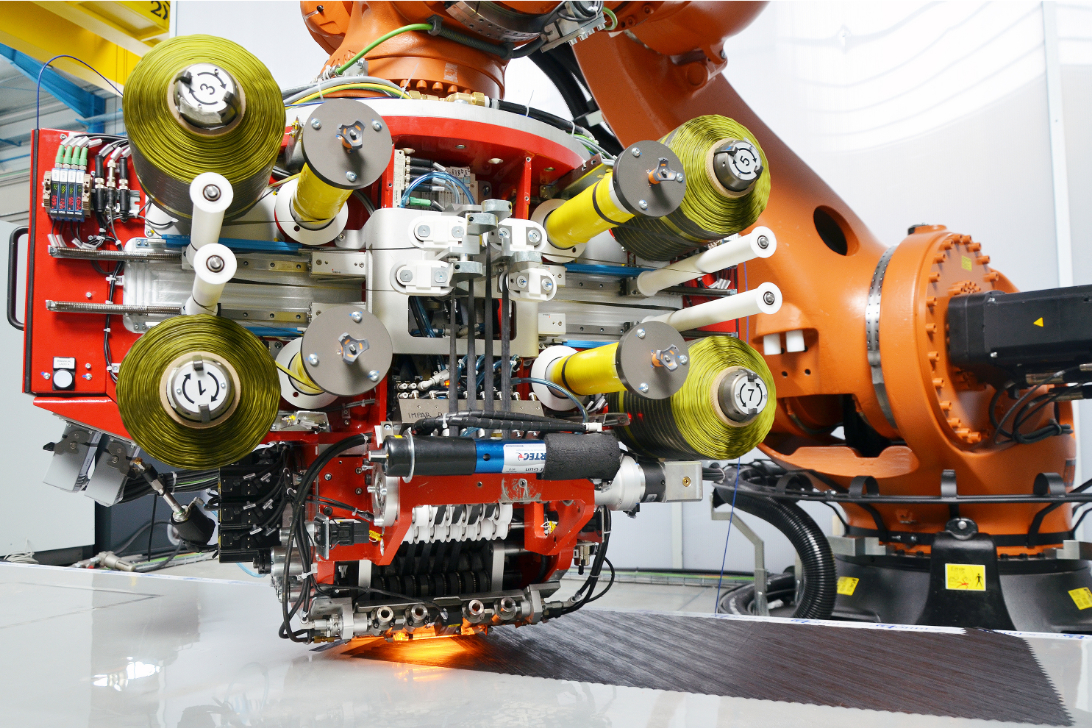

In the Automated Composites knowledge center, CGTech brings you vital information about all things automated composites, from the manufacturing processes to the vendors and necessary tools.

LEARN MORELatest Thermoplastics News And Updates

TAVieDA project team cuts aircraft door production time using thermoplastic composites, welding

Fraunhofer groups, Trelleborg and Airbus develop modular, fully automated assembly system concept to replace metals and time-consuming assembly that shows potential for scalability.

Read MoreAimen contributes to OVERLEAF 3D printed cryogenic tank

Dual thermoplastic composite system, developed to withstand temperatures below -250°C, demonstrates aviation decarbonization strategies.

Read MoreWickert press advances Chemnitz polymers, composites and metals research

Since its installation, the rapid heating/cooling press has become of great importance to the Institute for Lightweight Structures’ work in processing high-performance structural and hybrid components for industrial-scale applications.

Read MoreLehvoss Group expands reach of compounds, structural composites portfolio

Strategic partnership with PolySource will bring Lehvoss’ high-value materials to North American customers and expand PolySource’s technical capabilities.

Read MoreEngel supports composites upcycling research at TH Rosenheim

Engel Group has provided the Rosenheim University of Applied Sciences with a vertical injection molding machine for further R&D into the processing of thermoplastic, recyclable composites and the application of natural fibers.

Read MoreDiehl Aviation matures recyclable composite Eco Bin

Overhead baggage compartment using only fiber-reinforced thermoplastics, metal hardware and no adhesives wins Crystal Cabin Award, supports circular aircraft interiors.

WatchFeatured Posts

Thermoplastic composite pipes provide 59% reduction in H2 distribution CO2 emissions

Hive Composites’ multilayer thermoplastic composite pipe (TPC) design meets hydrogen permeation requirements while ensuring substantial CO2 reductions compared to conventional steel pipe systems.

Read MoreRecycled carbon fiber composite panels power 40% lighter, durable semi-rigid solar panels

Designed for auxiliary power use while traveling via boat or RV, Italian startup Levante’s custom flexible or standardized semi-rigid solar panels combine the benefits of ReCarbon’s rCF and thermoplastics.

WatchThe AAMMC Tech Hub: Ramping U.S. production of large thermoplastic composite aerostructures

CW talks with Syensqo, Spirit AeroSystems and other consortia members about current funding, specification of the next world’s largest press, organizational structure and projects to support U.S. companies in the race to deliver >40,000 sustainable and efficient aircraft over the next 20 years.

Read MoreJEC World 2025 highlights: New thermoplastics, PI fiber, solutions for FR, machining, digitized processes and more

CW senior technical editor Ginger Gardiner discusses latest developments in composites from this year’s show.

WatchPlant tour: Collins Aerospace, Riverside, Calif., U.S. and Almere, Netherlands

Composite Tier 1’s long history, acquisition of stamped parts pioneer Dutch Thermoplastic Components, advances roadmap for growth in thermoplastic composite parts.

Read MoreVIDEO: Installing the world’s largest thermoplastic composites press at Airbus Bremen

At JEC World 2025, Pinette PEI detailed its latest turnkey system for future aircraft serial parts production.

Watch