Composites 4.0

Plant tour: Hexagon Purus, Kassel, Germany

Fully automated, Industry 4.0 line for hydrogen pressure vessels advances efficiency and versatility in small footprint for next-gen, sustainable composites production.

Ginger Gardiner

Senior Technical Editor, CompositesWorld

Wichita State, Dassault Systèmes open Manufacturing Innovation Center

Aviation companies of all sizes will be able to improve their resilience and efficiency via the center’s virtual design, automation and additive manufacturing capabilities.

Read MoreFACC optimizes inspection processes through augmented reality

Cooperation with students from the University of Applied Sciences Upper Austria leads to successful use of AR, increasing the efficiency of components testing.

Read MoreSwinburne highlights composites and Industry 4.0 activities

Swinburne University of Technology’s facilities and research expertise have attained milestone developments in a UAV wingbox, customized carbon fiber components, digital manufacturing and 3D printing.

Read MoreEngel supports composites upcycling research at TH Rosenheim

Engel Group has provided the Rosenheim University of Applied Sciences with a vertical injection molding machine for further R&D into the processing of thermoplastic, recyclable composites and the application of natural fibers.

Read MoreTremonia Mobility delivers efficient, sustainable composite minibuses with Siemens Xcelerator

Minibus manufacturer adopts Siemens Xcelerator to advance electrification, improving design cycle speed by 20% and design adjustment speed by 30%.

Read MorePAIramid project drives digital approach to streamline composite aerostructures development, deployment

Multidisciplinary global team will leverage Al and data-driven simulations to make the aerostructure design, development and certification process faster, less costly and more reliable.

Read MoreModular, robotic cells enable high-rate RTM using any material format

Airborne’s automated ply placement systems at Airbus, GKN Aerospace and Teijin Automotive Technologies aim to maximize flexibility and intelligent automation.

Stewart Mitchell

Contributing Writer

Polaron AI materials design tool wins inaugural Manchester Prize

Generative AI model is capable of exploring thousands of material designs in under a day, providing an opportunity to more rapidly characterize and design advanced materials including alloys, composites and catalysts.

Read MoreASCEND program completion: Transforming the U.K.'s high-rate composites manufacturing capability

GKN Aerospace, McLaren Automotive and U.K. partners chart the final chapter of the 4-year, £39.6 million ASCEND program, which accomplished significant progress in high-rate production, Industry 4.0 and sustainable composites manufacturing.

Read MoreHexcel, FIDAMC join forces to shape future composites development, application and roadmap

Strategic alliance will accelerate the development of next-gen composite materials and their applications in high-impact industries.

Read MoreTeledyne CML Composites implements iBase-t digital manufacturing solution

Aerospace composites manufacturer advances its objectives to drive operational efficiency and quality via Solumina MES and EQMS.

Read MoreIMT Nord Europe launches COMPOLIS initiative

COMPOLIS is an R&I hub bringing together industrial partners, dedicated to connected materials and structures with the ultimate goal of digitalizing composite materials.

Read More4M Carbon Fiber to incorporate Carbonscreen AI monitoring system into plasma oxidation process

Letter of intent outlines steps to develop a real-time AL/ML monitor and control system to support automated, high-quality carbon fiber production.

Read MoreThermoplastic composites welding: Process control, certification, crack arresters and surface prep

More widespread use of welded composite structures within a decade? Yes, but further developments are needed.

Ginger Gardiner

Senior Technical Editor, CompositesWorld

D-STANDART project advances durability modeling of large-scale composite structures

D-STANDART is developing rapid methods to better characterize fatigue damage under real conditions for composites and supply chain sustainability. Results will be presented at JEC World 2025.

Read MoreAltair delivers AI-driven enhancements within HPCWorks 2025

Enhancements and additional capabilities further bolsters the software solution’s ability to support composites fabricators in an increasingly data- and AI-driven landscape.

Read MorePlataine earns Frost & Sullivan 2025 Technology Trailblazer Award

Agentic AI solutions are identified for their ability to help manufacturers operate at scale with agility and environmental responsibility.

Read MoreSiemens software chosen for JetZero BWB aircraft concept, launches Xcelerator updates

Aviation startup will use the Xcelerator platform to achieve its aircraft vision. Other Siemens collaborations deliver software additions to deliver, democratize industrial AI for small companies, startups.

Read MoreLeonardo unveils Proteus uncrewed rotorcraft demonstrator design

In the development of this fast-moving program, Leonardo is using a digital twin for synthetic development, more than 40 composite components and the use of AI in its control software.

Read MoreSchrödinger advances materials informatics for faster development of next-gen composites

Cutting time to market by multiple orders of magnitude, machine learning and physics-based approaches are combined to open new possibilities for innovations in biomaterials, fire-resistant composites, space applications, hydrogen tanks and more.

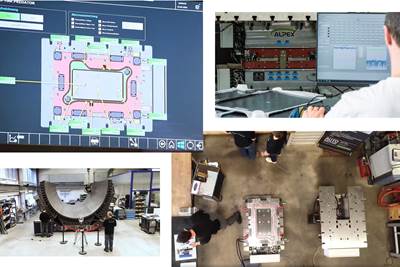

Read MoreDigitizing tools for composites production

Alpex Technologies focuses on industrialization, process and part intelligence and biocomposites in its next generation of tooling systems.

Ginger Gardiner

Senior Technical Editor, CompositesWorld

Circularise digital passports contribute to PU foam recycling

Under the Circular Foam initiative creating systematic approaches for efficient rigid polyurethane (PU) foam recycling, Circularise’s DPPs are advancing secure information traceability for recycling and consumers.

Read MoreAI Agents suite by Plataine orchestrates, automates and optimizes manufacturing operations

Enterprise-grade, interconnected agents automatically coordinate and balance operations between suppliers and customers to reduce workflow complexity, challenges.

Read MoreMaterialsZone launches integrated, AI-guided materials discovery platform

AI-Guided Product Development Feature introduction aims to make iterative AI models more accessible, empowering researchers and materials scientists with faster, smarter materials innovation.

Read MoreSAM XL demonstrates closed-loop digital methodologies via full-size aerocomposite parts development

PeneloPe Project’s modular, zero-defect manufacturing deliverables are being highlighted in an upcoming video that demonstrates the resulting aerospace pilot line’s feasibility.

Read MoreValeth partners with Plataine to optimize operations, increase production

By leveraging AI-driven automation, Valeth anticipates substantial improvements in composites operational efficiency and throughput.

Read MoreGeneral Atomics accelerates nuclear fuel digital twin testing, qualification

Under contract with the DOE, GA-EMS is advancing its SiGA silicon carbide (SiC) composite cladding technology to improve nuclear fuel efficiency and nuclear reactor safety.

Read More